January 6, 2008

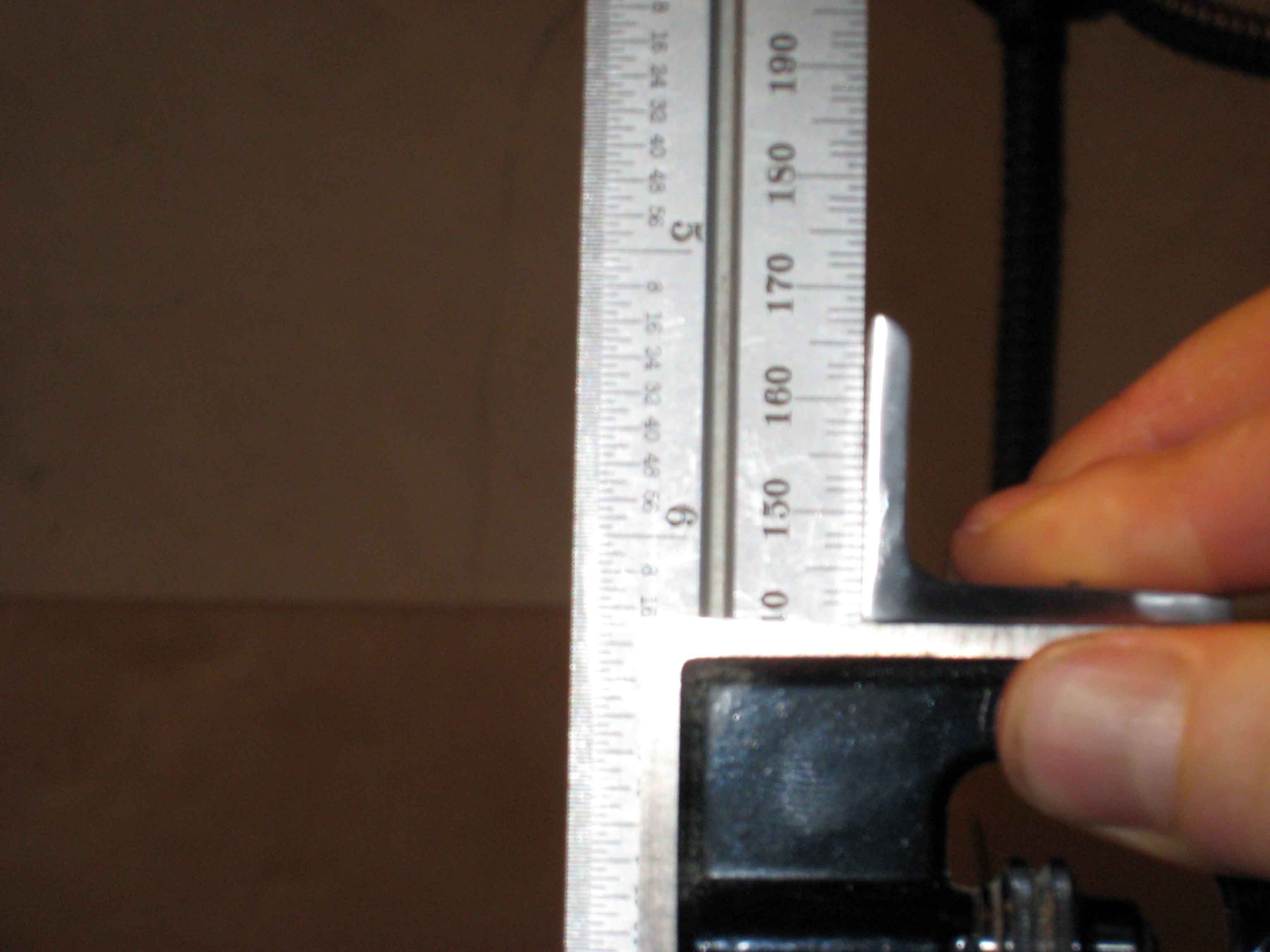

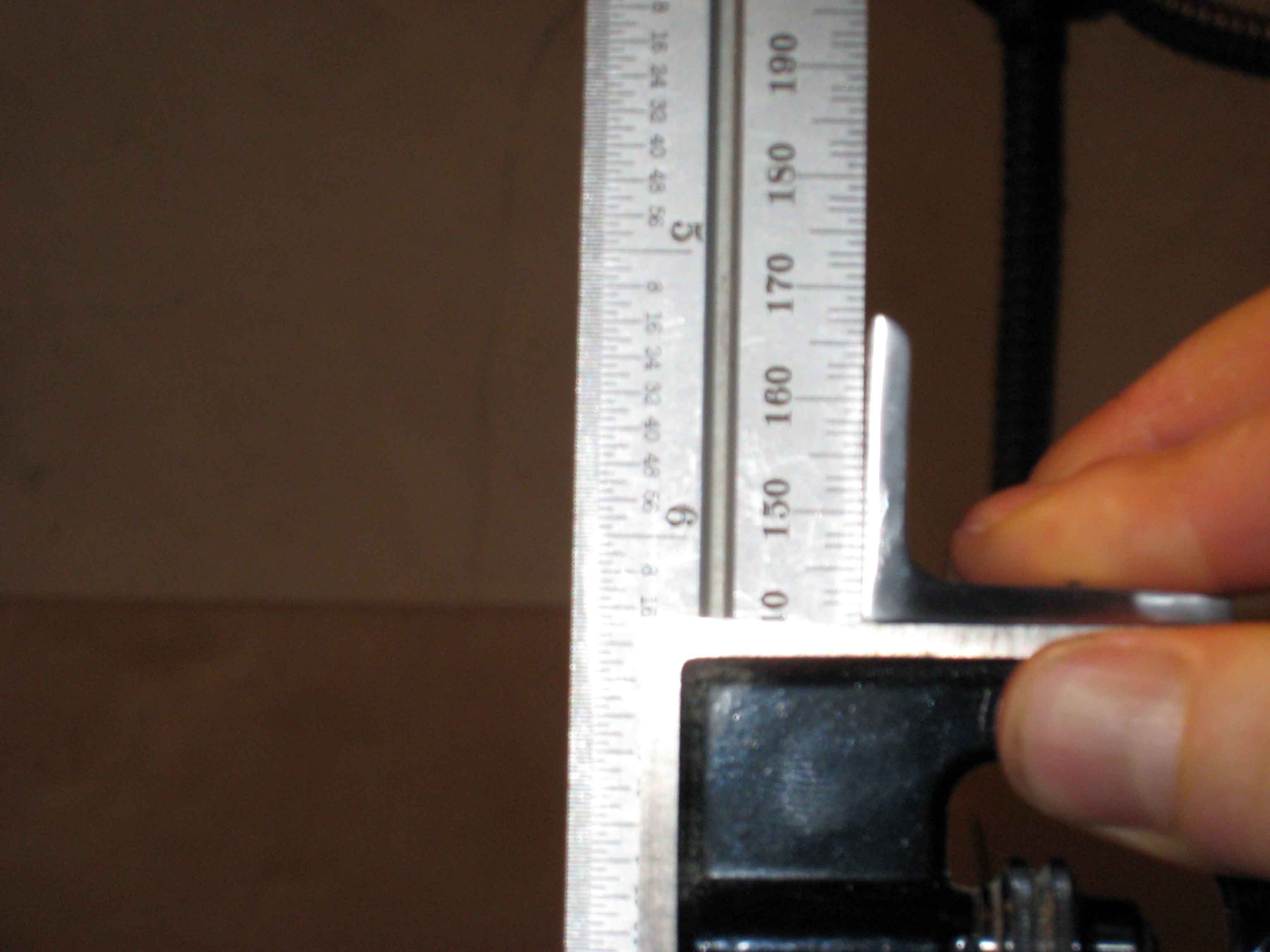

I'm going to try to go through all the steps with these rudder hinges first so I can go through the whole process once and then see what I mess up on. Now that I have my drilling method down I can continue. So the downside of this unibit is that the steps are only 3 mm long so I can't match drill the two hinges. Instead, I'm using a block to set the distance from the hinge base and drilling both holes without moving anything except swapping the metal.

Any side to side error is minimal and I leave the edge sanding until after I drill the hole so I can sand them so that the holes line up at the middle. I also sanded the hinge base to make the angle actually 90 degrees. These pictures are from after I polished the edges later in the day.

So these are now ready to be cleaned and alodined. After that, I'll press the bushing and then prime them. Sounds easy, right??

|

Tail Parts Menu

|

Home