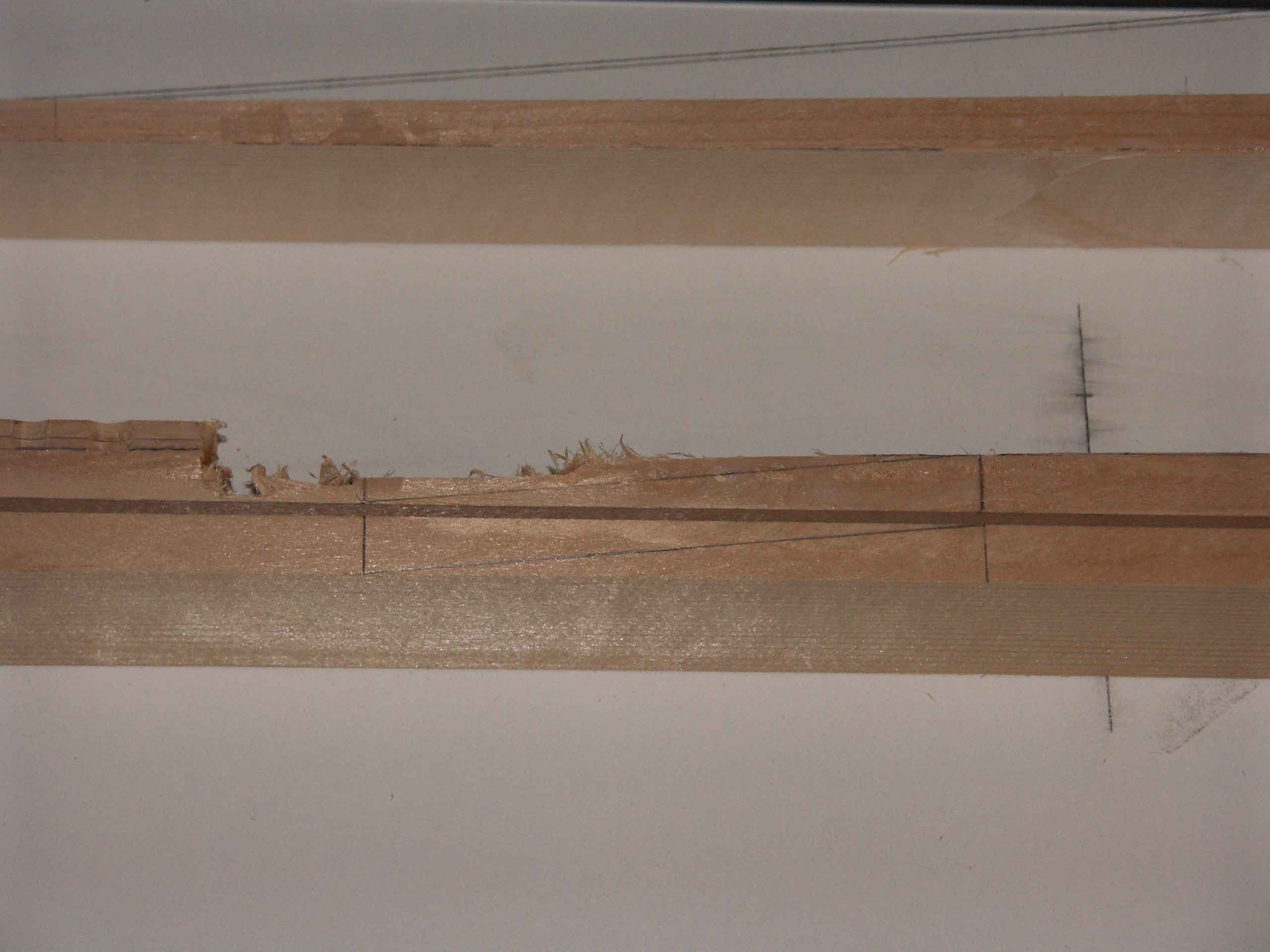

I definitely underestimated this job because it took a lot of effort. My idea was to do the taper in two passes, taking the upper half off first then do the real taper with the remaining. A lot of wood needs to come off, over 15 mm at the ends of the boom, which is why I split the job up. Things also didn't go exactly as planned. At first, I was having trouble getting a straight taper with my jig until I realized that the way I was clamping the boom to the jig was bending the straight channel. Once I had that figured out, I had to do two of the tapers over again. Then, on the last taper the router bit started to wiggle loose and then flew out. Apparently, I didn't put the bit in far enough. I didn't realize it at first so the bit really chewed up the spar before it came out. Luckily, the spar was chewed up after the point where the width was half so to fix it I just scarfed an extra piece of unlaminated spar boom onto the end, which I'll smooth out and finish the taper later.

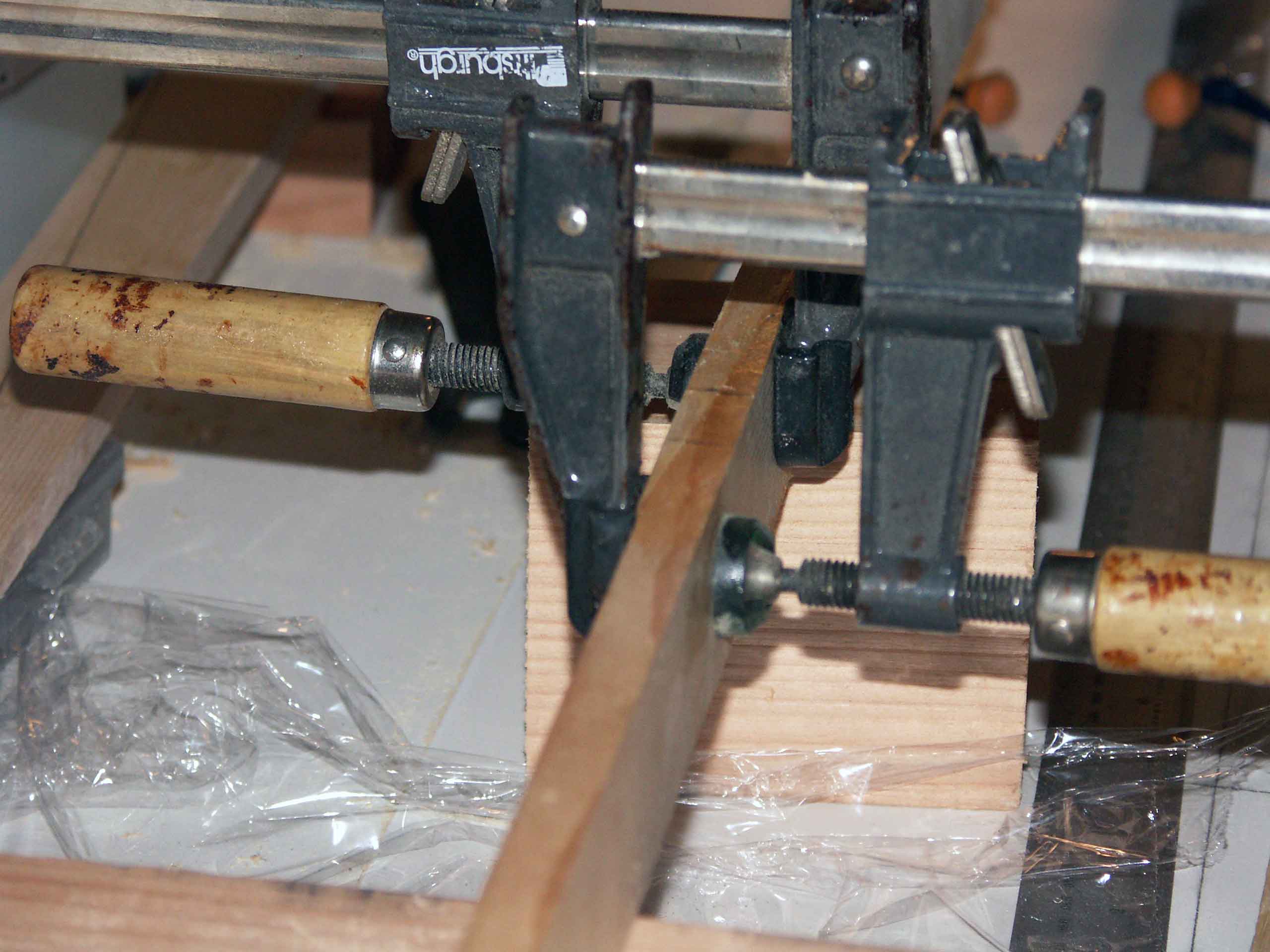

I glued some other odds and ends while I had the extra glue. The middle of the elevator spar gets another plywood pad and the main fin spar, which is actually the farthest back fuselage frame gets some strips to complete the frame shape at the bottom.

| Tail Parts Menu | Home