Now that didn't just happen with one shot. I really had to pound the crap out of it to get any results. The first 5 blows or so did nothing but dent the top of the raised block. The next few blows started cracking, and then shattering the block. In all, it took about 10 blows to get what you see here. I hit it squarely and hard each time.

What I was looking for here was to see if there was any failure along the glue line as the block came apart. There was one area that I was concerned about. The two pieces in the middle left of the pile looked like there had been some glue line failure. I asked around to people who know and they said that it was no problem and my test block definitely passed the test. Also, the fact that all the gluing I will be doing will be with spruce wood which is about half as strong in shear as maple...which is why you use maple for the test block. If the maple fails before the glue then spruce will definitely fail before the glue, making the glue the stronger part of the structure.

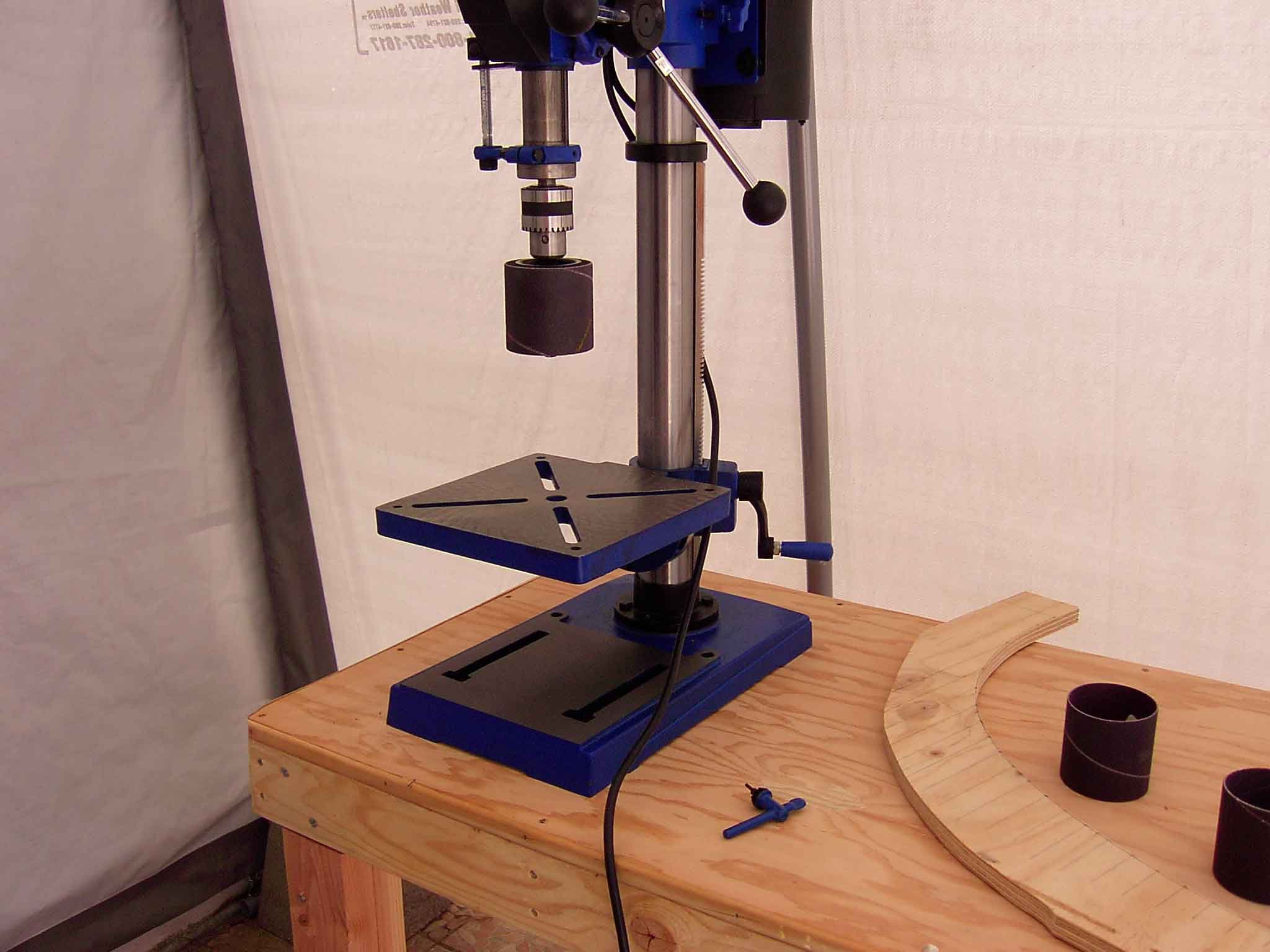

Today, I also set up the drill press with a drum sander to sand to the exact curve line that I cut out yesterday. I used medium grit sandpaper and it ate up the wood well and still left a pretty smooth finish. Here's a shot after I set it up and then a shot of the finished frame jig after sanding.

Over the next few days, I'll start setting things up for gluing so I'll be ready when I have the time and the heat to make the frame #2 diagonal. After I successfully make this one, I'll speed up a little bit with the other jigs. I want to go through and make at least this one frame, start to finish, before trying to streamline the process.